- Atmosphere-controlled furnace

- Tube furnace

- Gas Chromatograph

- Multifunction film coater

- Online Electrochemical Mass Spectrometer

- Bench-Top Semi-Automatic Screen Printing Film Coater with Vacuum Chuck

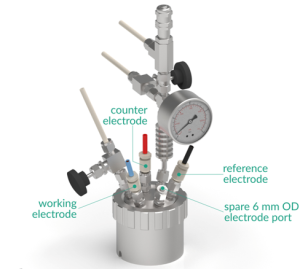

- High-Pressure Electrochemical H-Cell

- High-Pressure PEM Electrolysis Cell

-

Molybdenum Disilicide heating elements

- Maximum heating rate = 15°C/min

- Working atmosphere = Air, N2, Ar, NO2, CO, CO2, He, Ne, rough vacuum, Hydrogen, up to 5%.

- Chamber size = 10x7x7.5″ (254×177.8×190.5mm)

- Chamber volume = 0.44 ft3 (12.5 l)

Max Temperature:

- Air = 1700°C

- Helium (He), Neon (Ne), Argon (Ar) = 1650°C

- Nitrogen (N2) = 1500°C

- Hydrocarbon Gas = 1550°C

- Hydrogen (H2) up to 5% = 1500°C

- Rough vacuum = 1400°C

- Tube material = High purity (99%) Al2O3 alumina

- Minimum working temperature = 300°C

- Maximum working temperature = 1700°C

- Rated vacuum pressure = 0.001 Pa / 0.0075 millitorr / 0.00001 mbar

- Heating element = Molybdenum Silicide (MoSi2)

- Max heating & cooling rate = 5°C/min above 1200°C and 10°C/min below 1200°C

- Tube size = 60mm x 1300mm (OD x length)

- Thermal conductivity detector (TCD)

- Methanizer in series with an flame ionization detector (FID)

- 2 heated valves, 10 port for gas injection and backflush to vent and 6 port for series/bypass

- Porous polymer column for CO2 and light hydrocarbons up to butane.

- Molecular sieve 5A column for O2/Ar, N2, methane, H2 and CO.

- Methanizer for conversion of CO and CO2 to methane.

- Coating width: 180 mm for roll to roll coating

- 250mm for sheet coating ( 500mm in length )

- Maximum heating temperature: 120 ºC.

- Heating rate up to 1.2 ºC/s.

- 20 – 200 micron thickness adjustable

- 40KHz ( 220VAC/130W) ultrasonic generator for Roll-to-Roll spray coating

- High voltage supply for Roll-to-Roll electrospinning

- Multiple gas and vapour analysis: 0 – 300 amu mass range option

- Multiple options of gas sample flow rate: 12 µl/min – 16 ml/min

- Continuous sampling heated capillary inlet. Heating dependent on selected flow rate

- Real time, multispecies analysis: detection from 100 ppb – 100%

- Response times as fast as 300 ms

- Fast data acquisition: up to 1000 measurements per second

- Electrode deposition on various supports

- Effective printing area: 280 x 350 mm Max.

- Substrate thickness: 0 – 80 mm adjustable

- Custom screen can be produced with different electrode patterns

- Holds Screen Mask within Length: 300 – 600mm and Width: 200 – 350mm

- Maximum operating pressure: 25 bar

- Maximum operating temperature: 200°C

- Electrocatalysts characterization at high pressure

- Membrane mechanical and transport performance

- Novel electrode testing

- Cell active area: 25 cm²

- Maximum working pressure: 30 bar

- Flow field design: triple serpentine (other on request)

- Anode flow field (PEM): platinum coated titanium (grade II)

- Cathode flow field (PEM): gold coated titanium (grade II)